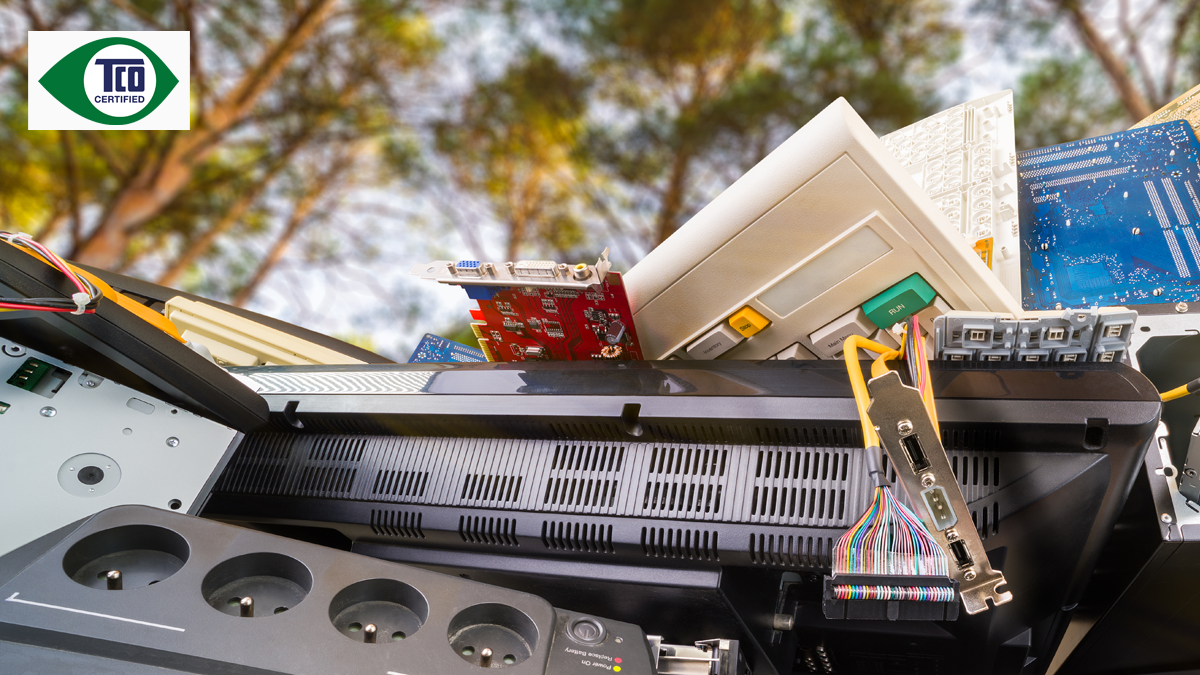

E-waste is a mounting problem in the UK – and the world – which is why development of the circular economy is so important. Organisations such as TCO Certified are helping to encourage businesses and manufacturers to be more circular in their operations.

The amount of e-waste continues to grow – and so does the problems it poses. On January 24, the annual Circular Electronics Day was held to highlight the problem – and how it can be addressed.

Circular Electronics Day is a global initiative that underscores the environmental and social impacts of e-waste and champions sustainable practices in the production, use and recycling of electronics.

“Estimates are that between 2010 and 2030, e-waste will double,” explains Claire Hobby, director, Purchaser Engagement, Global at TCO Certified. “By 2030, it could about 84 billion kilos a year, globally. The problem is the amount of e-waste we’re putting out to the world is rising five times faster than what we’re capturing and recycling and reusing.

“So as staggering as the numbers are, it’s the trend that is really concerning. Our behaviours are perpetuating this linear economy over and over again. That’s probably our biggest concern, we’re putting more products out there, we’re not getting them back, and we’re not using them long enough to reduce those life cycle impacts. It’s a huge problem.”

Influencing manufacturers

Many products are not being recycled once they have finished their working life and often end up in landfill, which adds to the problems of greenhouse gas emissions. Claire says that some products are still designed to be discarded in a few years and replaced. This is something that TCO Certified, as a global provider of sustainability certification for IT products for more than 30 years, is challenging.

“In the IT space we’re trying to influence that first design phase,” says Claire. “The products we’re going to be using in four or five years are in the design phase right now. We need to make sure that we can replace the batteries and components rather than assume that we’re going to use it for a certain amount of time and then it ends up in landfill.

“We look to influence the design and manufacturing of IT products so when they get into the market users can use them for longer, replace parts, refurbish them and keep that lifecycle going. And, when a device has reached the end of its life, we can bring those materials back, recycle them and give them a second life.

“It’s about finding those drivers that make the IT industry do things differently because it has made a lot of money on a linear economy and getting it into our mindset to replace a computer every three years with a more energy-efficient one. That’s not the best thing we should be doing. We’ve got to as consumers, as large buyers, as government institutions, put pressure on the IT industry to do things differently.”

Sustained demand for sustainability

This is now happening. Claire adds that there is more demand for sustainable products across the board and the brands understand this, which is why they look for certification from TCO Certified to show their credentials. The tightening regulatory landscape, especially in Europe, is also focusing minds on sustainability.

While there are geopolitical concerns, with some nations looking to loosen environmental policies, Claire believes that IT manufacturers are wedded to sustainability for the long-term.

“This work in better product design, lowering lifetime emissions, getting supply chains more carbon responsible, these commitments were made many years ago,” she says. “That work continues; these are not initiatives that they can just turn on and off. These commitments have been made and there’s plenty of the world that are still putting on the heat for sustainability to happen. These commitments aren’t going away.”

Reseller role

Resellers have their role to play too in helping customers to adopt more circular practices – although some need to up their game, Claire warns. “We’ve seen ourselves, but we’ve also heard from some brands that resellers aren’t up to speed on some of this stuff sometimes,” she says. “They are at the frontline of addressing the end users with this information about sustainability.

“We all need to do a better job of making sure the reseller community is up to speed on sustainability, what they can offer end users, and we need to be greenwash free, too. We need to tell them that it’s not about buying a new product every two or three years, it’s about using what you have longer because we’ve got more than 80% of those lifetime emissions locked in that supply chain.

“We must find a way to get resellers on board. For example, we have one reseller we work with in Singapore that has adopted a circular model where they will sell a product, put it into the market for four years, then take it back, refurbish it, and then put it back into healthcare and education settings for another four years.

“One of the big pushes for that is to help the end users understand the reduction in carbon emissions just by extending the life. It’s been an interesting exercise in making sustainability a central part of their value proposition to their customers. There’s stories like this out there that we need to do a better job of telling, and resellers are key to that message.”

Challenges remain

Of course, there is much more that could be done to enhance circularity, and TCO Certified is helping the industry to work towards this.

“These products are well refurbished now,” says Clare. “One of the challenges the industry has is gathering around common ways of dealing with these products at scale. The refurbishers might get a certain number of products of a certain model in, but we’d love to see companies coming in with 500 of these the same model, refurbish them as a lot, and then put them back into the market. It’s a much more attractive proposition. The more we do it, I believe the more we can perpetuate that.”

More could also be done to improve the traceability of components through a product’s lifecycle, Claire adds. “We talk about things like digital product passports that are going to be hugely important in this space,” she says. “If we’re going to recycle and refurbish something, we need to know where it’s been and where these components came from. We need to be able to trace them back to their origin.”

However, she acknowledges that IT is complex regarding tracking how sustainable a product really is. “You’ve got literally thousands of steps to making a computer,” she says. “How is a buyer supposed to know what they’re actually getting? That’s where independent verification comes in. We need to get in there and test these products.

“Look at battery life, for example, something that historically has often been overestimated. You have a declaration of a certain number of battery cycles, but when we go in and test that, it’s often been shown to be less.” Things like that we need to address with independent verification. That’s what we try to do in TCO Certified. We go into factories, test products, really see what’s included in them because buyers need to trust what we do. We’re emerging from an era where buyers have just taken what vendors tell them at face value. They’re getting smarter, they know the questions to ask and that’s a positive for the market.”

Future

TCO Certified has a 10-year roadmap to push the agenda for extending the lifecycle of IT products. “We’re pushing hard to make this mainstream,” Claire says. “There are organisations wanting to buy refurbished and recycled, but this doesn’t happen overnight. We need everyone to get on board.

“We want to focus on extending the supported life of products. One of the biggest barriers to circular use of products is that the software is not supported, security patches are not supported, and there’s a lack of extended warranties that are affordable. Those are big things standing in the way of buyers using devices for longer. They want to do it, they’re prepared to do it, but it’s these ecosystem issues that stand in the way.

“We’re putting in requirements to increase the number of years that the brands must support a product. We’re asking minimum five years, and that’s mandated in our criteria. We’re also looking at the amount of takeback the brands will be required to do. Our vision is pushing further for supported lifetimes, easier refurbishment opportunities, replaceable components and the like.

“We’re also curious about new business models. Product as a service, for example, different leasing models. If these products are being circulated, rebuilt, and repurposed, then those new business models can be interesting as well.”

Claire is optimistic for the future and addressing the problem of e-waste. “We’re beginning to see some good examples coming through,” she says. “For instance, in Australia there is a new policy coming out in July that looks at circular use. Europe is doing all kinds of good work in this space as well. There’s definitely progress. We’ve got the retailer community starting to come on board as well. We need to unlock even more user demand for this, as that will be the signal that gets the whole machine moving faster.”